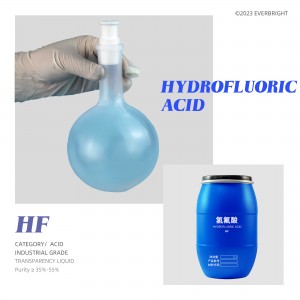

HYDROFLUORIC ACID/HF

SPECIFICATIONS PROVIDED

transparency liquid Purity ≥ 35%-55%

EVERBRIGHT® ‘ll also provide customized :

content/whiteness/particlesize/PHvalue/color/packagingstyle/ packaging specifications

and other specific products that are more suitable for your use conditions , and provide free samples.

PRODUCT DETAILS

Hydrogen fluoride gas is soluble in water, and its aqueous solution is called hydrofluoric acid. The product is often 35%-50% aqueous solution of hydrogen fluoride gas, the highest concentration can reach 75%, and it is a colorless and clarified smoking liquid. Pungent odor, volatile, white smoke in the air. It is a medium strength inorganic acid, highly corrosive, and can erode glass and silicates to produce gaseous silicon tetrafluoride. It can also interact with metals, metal oxides and hydroxides to form various salts, but the effect is not as intense as hydrochloric acid. Gold, platinum, lead, paraffin and some plastics do not work with it, so containers can be made. Hydrogen fluoride gas is easy to polymerize, forming (HF) 2 (HF) 3·· iso-chain molecules, in the liquid state, the degree of polymerization increases. Store in containers made of lead, wax or plastic. It is highly toxic and ulcerates upon skin contact.

PRODUCT USAGE

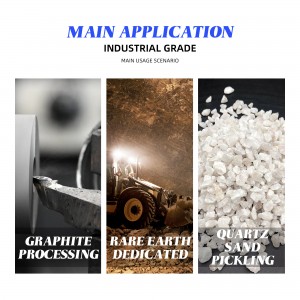

INDUSTRIAL GRADE

Graphite processing

Hydrofluoric acid is a strong acid that can react with almost any impurities in graphite, and graphite has good acid resistance, especially can be resistant to hydrofluoric acid, which determines that graphite can be purified with hydrofluoric acid. The main process of hydrofluoric acid method is the mixture of graphite and hydrofluoric acid, and the reaction of hydrofluoric acid and impurities for a period of time to produce soluble substances or volatiles, after washing to remove impurities, dehydration and drying to obtain purified graphite.

Rare earth Dedicated

The preparation of anhydrous rare earth fluoride is by precipitation of hydrated rare earth fluoride from aqueous solution, then dehydration, or direct fluorination of rare earth oxides with fluorinating agents. The solubility of rare earth fluoride is very small, and the use of hydrofluoric acid can precipitate it from the hydrochloric acid, sulfuric acid or nitric acid solution of rare earth (the precipitate is in the form of hydrated fluoride).

Metal surface treatment

Remove surface oxygen-containing impurities Hydrofluoric acid is a weak acid, similar in strength to formic acid. The general concentration of commercially available hydrofluoric acid is 30% to 50%. The main features of hydrofluoric acid rust removal are as follows: (1) Can dissolve silicon-containing compounds, aluminum, chromium and other metal oxides also have a good solubility, commonly used to etch castings, stainless steel and other workpieces. (2) For steel and iron workpieces, low concentration hydrofluoric acid can be used for rust removal. Aqueous solution of hydrofluoric acid with a concentration of 70% has passivation effect on steel (3) Hydrofluoric acid with a concentration of about 10% has a weak corrosion on magnesium and its alloys, so it is often used for the etching of magnesium workpieces. (4) Lead is generally not corroded by hydrofluoric acid; Nickel has strong resistance in hydrofluoric acid solutions with concentrations greater than 60%. Hydrofluoric acid is highly toxic, and volatile, when used to prevent human contact with hydrofluoric acid liquid and hydrogen fluoride gas, the etching tank is best sealed and has a good ventilation device, fluorinated wastewater can be discharged after treatment.

Quartz sand pickling

It works best when treated with hydrofluoric acid, but requires a higher concentration. When shared with sodium dithionite, lower concentrations of hydrofluoric acid can be used. A certain concentration of hydrochloric acid and hydrofluoric acid solution were mixed into the quartz sand slurry at the same time according to the proportion; It can also be treated with hydrochloric acid solution first, washed and then treated with hydrofluoric acid, treated at high temperature for 2-3 hours, and then filtered and cleaned The impurities and oxides on the surface of quartz sand can be effectively removed, and the purity and quality of quartz sand can be improved.

FOCS Fiber corrosion

Hydrofluoric acid filling corrosion of photonic crystal fiber (PCF) was developed. Hydrofluoric acid was filled into the air hole of drawn photonic crystal fiber. By changing its cross section structure, the photonic crystal fiber with specific structure was developed to change its light conductivity. The results show that the leakage loss and scattering loss decrease with the corrosion degree of the air hole of the photonic crystal fiber, the nonlinear coefficient increases obviously, the effective refractive index of the core mode and the equivalent refractive index of the cladding decrease correspondingly, and the group velocity dispersion also changes.

ELECTRONIC GRADE

TPT-LCD screen thinning

Under the protection of photoresist and border glue, the concentration of hydrofluoric acid is adjusted, a certain amount of nitric acid, concentrated sulfuric acid and hydrochloric acid are added, and the ultrasonic auxiliary conditions are added, the etching rate is obviously improved. The surface roughness is effectively reduced by alternating cleaning processes, and the precipitation of white surface attachments is reduced. Solve the problem of rough surface and white surface adhesion precipitate.