POLYACRYLAMIDE/PAM

SPECIFICATIONS PROVIDED

Anion/cation/non-ion/zwitterion formula weight : 6 to 12 million

cation(CPAM) :In sewage treatment as flocculant used in mining, metallurgy, textile, paper and other industries. It is used in various operations in the petroleum industry.

anion(apam) :In industrial wastewater (electroplating plant wastewater, metallurgical wastewater, steel plant wastewater, coal washing wastewater, etc.) plays a flocculation and precipitation role.

zwitter-ion(ACPAM) :1, profile control and water blocking agent, after oilfield tests, the performance of this new zwitterion profile control and water blocking agent is higher than other single ion characteristics of profile control and water blocking polyacrylamide agent. 2, in many cases, when treating sewage and water, the combination of anionic polyacrylamide and cationic polypropylene is more significant and synergistic than the use of an ionic polyacrylamide alone. If the single two are used improperly, they will produce white sediment and lose the effect of use. So the use of complex ionic polyacrylamide effect is better.

NON-ION(NPAM) :Clarification and purification function, sedimentation promotion function, thickening function and other functions, filtration promotion function. In the waste liquid treatment, sludge concentration and dehydration, mineral processing, coal washing, paper making, etc., it can fully meet the requirements of various fields. The simultaneous use of non-ionic polyacrylamide and inorganic flocculants (polyferric sulfate, polyaluminum chloride, iron salts, etc.) can show greater results.

EVERBRIGHT® ‘ll also provide customized :

content/whiteness/particlesize/PHvalue/color/packagingstyle/ packaging specifications

and other specific products that are more suitable for your use conditions , and provide free samples.

PRODUCT DETAILS

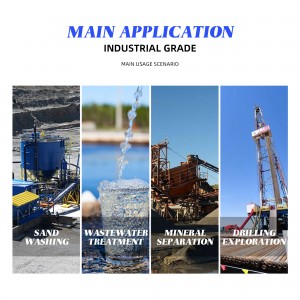

PRODUCT USAGE

INDUSTRIAL GRADE

In order to remove impurities (such as dust) from sand products, more water washing methods are used, so it is called For sand washing. In the sand, gravel, sandstone washing process, flocs The sedimentation speed is fast, the compaction is not loose, and the discharge water is clear. Sand washing wastewater can be completely treated The water body can be discharged or recycled.

COAL CLEANING

Coal mines are mixed with many impurities in the mining process, and because of the different quality of coal, it is needed Impurities in raw coal are removed by coal washing, or high-quality coal and inferior coal are distinguished. Our products have the advantages of fast flocculation speed, clear effluent water quality and low water content of sludge after sludge dewatering Features. After treatment, the coal washing wastewater can reach the standard completely, and the water body can be discharged and recycled.

Mineral separation

Beneficiation is the separation of useful minerals from gangue minerals to remove or reduce harmful impurities The process of obtaining raw materials for smelting or other industries. The application feature of the process is daily sewage treatment The amount is large, so the slag flocculation speed is fast, the dehydration effect is good, and the sewage treatment process is more Using the circulating water process, the above product selection is specifically for metal ores and non-metallic ores Research and development of mineral processing technology for precious metals such as stone, gold and platinum.

papermaking

In paper industry, straw and wood pulp are used as raw materials for paper making, so the composition of paper making wastewater is complex, and paper making wastewater is the main industrial pollution in China One of the dye sources, poor biodegradability, belongs to the more difficult to treat wastewater type. After the use of flocculant, the flocculation rate of papermaking wastewater is fast, the flocculation compactness is high, and the pollution is high The mud has low moisture content and clear water quality.

Industrial/Municipal wastewater treatment

①Waste water and waste liquid produced in the industrial process, which contains industrial production materials, intermediate products, by-products lost with water and in the production process The pollutants produced result in a wide variety of industrial wastewater, complex composition, difficult to treat. 85 series products for industrial wastewater slaughtering, printing and dyeing, electroplating metallurgy The wastewater treatment effect of gold, leather manufacturing, battery waste liquid and so on is excellent, the solid content of the sludge after dehydration is high, the mud mass is compact and not loose, and the effluent water quality is stable.

②There are a lot of organic matter and bacteria, viruses in the urban sewage, so the sewage is collected by the urban canal and treated by the urban sewage treatment plant before entering the water Body. With the characteristics of fast flocculation rate, increased sludge volume, low water content of sludge and stable effluent water quality after treatment, it is suitable for all kinds of raw materials Centralized treatment of live sewage and industrial sewage.

DRILLING EXPLORATION

Usually exploration or development of oil, natural gas and other liquid and gaseous minerals, need to use mechanical equipment or manpower from the ground to drill holes or large diameter water supply Well engineering. The use of products in the field drilling, exploration or development of oil can improve the rheology of drilling fluids, carry cuttings, lubricate drill bits, and improve rotation Quick. It can greatly reduce stuck drilling accidents, reduce equipment wear, prevent leakage and collapse. Most require a certain salt resistance, temperature resistance, the later viscosity requirements are too high 99 granule series is recommended.

DRILLING EXPLORATION

Usually exploration or development of oil, natural gas and other liquid and gaseous minerals, need to use mechanical equipment or manpower from the ground to drill holes or large diameter water supply Well engineering. The use of products in the field drilling, exploration or development of oil can improve the rheology of drilling fluids, carry cuttings, lubricate drill bits, and improve rotation Quick. It can greatly reduce stuck drilling accidents, reduce equipment wear, prevent leakage and collapse. Most require a certain salt resistance, temperature resistance, the later viscosity requirements are too high 99 granule series is recommended.

TERTIARY OIL RECOVERY

The use of chemicals to improve the performance of oil, gas, water and rock to recover more oil is called tertiary oil recovery. Improving oil recovery In the tertiary oil recovery methods, the use of polyacrylamide as oil displacement agent plays an important role. The product is used in the tertiary oil recovery stage, increasing the displacement capacity to achieve The purpose of improving the efficiency of oil bed exploitation.

PILING

In the process of building piling and oilfield construction, in order to make the building foundation strong, special machines are used to drive, press, vibrate or rotate piles of various materials In the construction of foundation soil, PAM is added to ensure that the soil is firm and not loose. It has fast penetration, high viscosity, and is not easy to degrade in later period Features.

INCENCE MAKING

The use of chemicals to improve the performance of oil, gas, water and rock to recover more oil is called tertiary oil recovery. Improving oil recovery In the tertiary oil recovery methods, the use of polyacrylamide as oil displacement agent plays an important role. The product is used in the tertiary oil recovery stage, increasing the displacement capacity to achieve The purpose of improving the efficiency of oil bed exploitation.

PILING

In the process of building piling and oilfield construction, in order to make the building foundation strong, special machines are used to drive, press, vibrate or rotate piles of various materials In the construction of foundation soil, PAM is added to ensure that the soil is firm and not loose. It has fast penetration, high viscosity, and is not easy to degrade in later period Features.